Choosing the right backpack sprayer piston vs diaphragm pump is a critical decision that directly impacts operational uptime, chemical costs, and worker safety. A mismatch between the pump mechanism and the chemical agent leads to premature seal failure, inconsistent application pressure, and unscheduled downtime, turning a routine task into a costly operational risk.

This guide provides a clear technical comparison of both pump systems. We will analyze the core mechanics of piston and diaphragm designs, evaluate their performance against critical metrics like pressure output and chemical compatibility, and outline the maintenance demands for each. Use this breakdown to standardize your equipment selection process and ensure you deploy the most durable and efficient pump for every job.

What Is a Backpack Sprayer Pump and Why It Matters

The pump is the core component of any backpack sprayer, directly controlling pressure, chemical compatibility, and overall application performance.

The Core Function of a Backpack Sprayer Pump

A backpack sprayer pump is the mechanical system that creates pressure inside the spray tank and pushes liquid through the hose, lance, and nozzle. Whether you are applying pesticides, herbicides, fertilizers, disinfectants, or public health chemicals, consistent pressure ensures uniform spray coverage and proper droplet size. Backpack sprayers typically use one of two pump systems: piston pump and diaphragm pump.

- Creates pressure to atomize and propel fluids.

- Dictates the spray reach, pressure level, and droplet size.

- Determines which types of chemicals the sprayer can safely handle.

Low or unstable pressure leads to uneven application, chemical waste, and crop damage. Excessively high pressure can cause misting drift and environmental concerns. Therefore, selecting the correct pump type is a practical decision that impacts field performance and product reliability.

For a detailed breakdown of different models and their structural variations, explore our comprehensive guide on the types of knapsack sprayer to find the ideal base configuration for your operations.

How a Piston Pump Works in a Backpack Sprayer

A piston pump uses a reciprocating piston inside a cylinder, leveraging one-way check valves to draw in fluid and then forcefully eject it under high pressure.

Piston pumps use a cylinder and piston mechanism to build high pressure, often reaching up to 90 PSI. The piston pump operates through a simple, reciprocating action. A piston moves up and down inside a sealed cylinder, using one-way valves to draw fluid from the tank and push it toward the spray nozzle.

On the upstroke, the piston creates a vacuum that pulls liquid from the tank through an inlet check valve into the pump cylinder.

On the downstroke, the piston pushes down, closing the inlet valve and forcing the trapped liquid out through an outlet check valve. The operator’s manual pumping of the sprayer handle drives this cycle, creating a pressurized flow for spraying.

How a Diaphragm Pump Works in a Backpack Sprayer

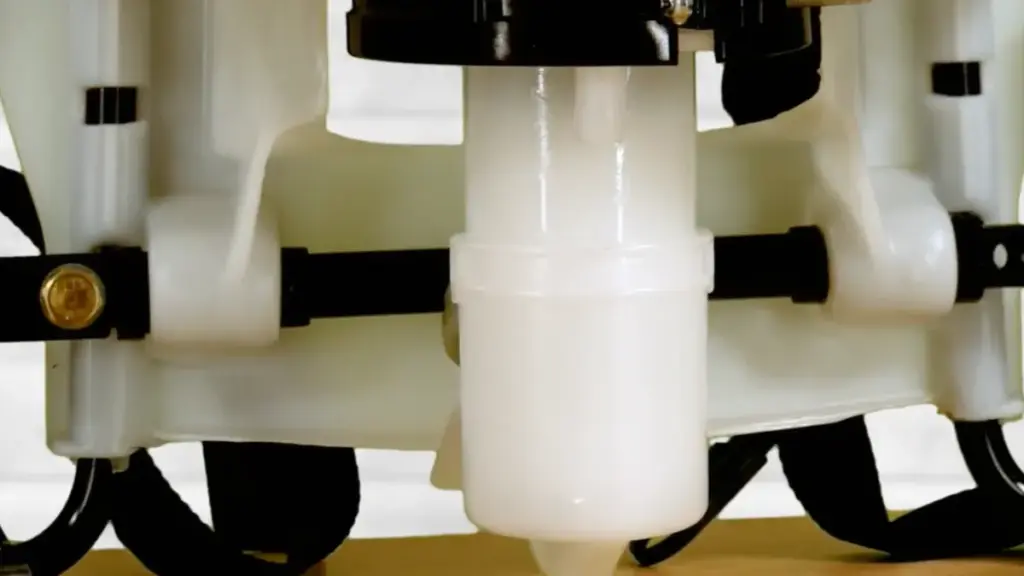

A diaphragm pump uses a flexible, oscillating membrane to move fluid, a design that isolates mechanical components from the chemical solution and allows for handling abrasive or corrosive materials.

A diaphragm pump operates using a flexible, circular membrane that moves back and forth within a sealed chamber. This membrane, often fabricated from chemically resistant elastomers like Viton, creates a seal that separates the mechanical drive components from the fluid being pumped. As the diaphragm moves back and forth, it alters the volume of the pump chamber, directing fluid through a series of one-way valves.

- A flexible elastomer diaphragm is sealed against the pump housing, creating a pumping chamber.

- As the diaphragm pulls back, it increases the chamber’s volume, creating a vacuum that draws liquid in through an inlet valve.

- When the diaphragm pushes forward, it reduces the chamber’s volume, pressurizing the liquid and forcing it out through an outlet valve.

Power Your Profits with Durable Agricultural Machinery

A Comparison of Piston Pump vs. Diaphragm Pump

To assist in your selection process, we have summarized the primary technical differences between piston and diaphragm pumps below.

| Feature / Metric | Piston Pump System | Diaphragm Pump System |

|---|---|---|

| Maximum Pressure | High (Up to 90+ PSI) | Typically around 60 PSI |

| Chemical Compatibility | Liquid concentrates, clear water-based solutions | Wettable powders, bleach, abrasive & corrosive formulas |

| Mechanism Design | Internal sliding piston with mechanical cylinder seals | Reciprocating flexible membrane (Viton/Santoprene) |

| Best Applications | Orchards, tall tree care, fine misting requirements | Commercial pest control, industrial disinfection, farming |

| Durability Profile | Sensitive to grit; requires strictly filtered liquids | Isolated drive system; highly resistant to internal wear |

| Maintenance Profile | Frequent but straightforward seal/O-ring replacement | Infrequent service; involves membrane and valve check |

| Reach & Atomization | Superior reach and finer droplet atomization | Standard reach; optimized for controlled drift |

Pressure Output and Spray Performance

Piston pumps are engineered for high-pressure work, creating a fine mist that provides uniform coverage. Diaphragm pumps run at lower pressures, producing larger droplets that reduce drift. This makes them a better fit for targeted applications where overspray is a primary concern.

- Piston pumps generate much higher pressure, often exceeding 90 psi, which is needed to hit distant targets and create fine, atomized sprays.

- Diaphragm pumps typically operate around 60 psi, resulting in larger, heavier droplets that minimize wind drift.

- The choice directly affects spray quality. The higher pressure from a piston pump gives thorough coverage for insecticides, while the lower pressure from a diaphragm pump is better for applying herbicides without harming nearby plants.

Chemical Compatibility and Corrosion Resistance

Diaphragm pumps have superior compatibility with abrasive and corrosive chemicals. Many agricultural fungicides and insecticides are formulated as wettable powders (WP) or water-dispersible granules (WDG). These solutions contain small, abrasive particles. In a piston pump, these particles become trapped between the piston seal and the cylinder wall, leading to scoring and loss of compression.

However, diaphragm’s enclosed design shields mechanical components from direct liquid contact, preventing accelerated wear. Piston pumps are far more vulnerable to damage when used with gritty or harsh formulas.

- The flexible diaphragm isolates the pump’s moving parts from the chemical solution, making it highly resistant to abrasive materials like wettable powders and corrosive liquids.

- In a piston pump, the chemical flows directly over the piston and its seals. This increases the risk of abrasion and premature wear, especially with non-liquid formulas.

- For spraying bleach solutions, suspensions, or other aggressive chemicals, a diaphragm pump delivers greater reliability and a longer service life.

Durability, Wear Parts, and Maintenance

Diaphragm pumps are generally more durable and require less frequent maintenance. Their simple design has fewer high-friction parts. Piston pumps need more regular servicing of seals and cylinders but are often designed for quick field repairs.

- Diaphragm pumps have a longer operational lifespan between services because there is no direct friction between moving parts and cylinder walls, minimizing mechanical wear.

- Piston pumps rely on seals that wear down from friction and chemical exposure. These require periodic replacement to maintain pressure.

- While diaphragm pump repairs can be more complex, their maintenance intervals are much longer. Piston pumps need more frequent attention but are often easier for users to service quickly.

Best Applications for Piston Pump Backpack Sprayers

Piston pump sprayers are the standard for high-pressure, precision applications like spot treatments and pest control, where a fine mist is required for effective coverage with liquid-only formulations.

Spot Treatment and Weed Control

Piston pumps excel at delivering herbicides with precision. Their ability to produce a fine, targeted mist at high pressure ensures that chemicals are applied directly to weeds without drifting onto nearby desirable plants. This consistent spray pattern is ideal for controlling invasive species in garden beds, lawns, and along fence lines. The high pressure also helps penetrate dense foliage, ensuring the herbicide reaches its target effectively.

Pest and Disease Management

When applying insecticides and fungicides in gardens, small orchards, or greenhouses, a piston pump provides the fine droplet size needed to evenly coat leaves and stems. This fine mist adheres well to plant surfaces, maximizing the effectiveness of the treatment and ensuring comprehensive plant protection. The technology is well-suited for treating ornamental plants, vegetables, and fruit trees where thorough coverage is essential for disease prevention.

Lawn Care and Turf Management

Maintaining healthy turf often requires applying liquid fertilizers, herbicides, and growth regulators. Piston pump sprayers offer the control and consistent output necessary for uniform application across lawns. The high-pressure spray ensures even distribution of liquid treatments, preventing patchy or uneven results. Its portability makes it a practical tool for managing turf in residential yards, commercial properties, and athletic fields.

Best Applications for Diaphragm Pump Backpack Sprayers

Diaphragm pumps are the go-to choice for applications involving abrasive powders, mildly corrosive solutions like bleach, and low-pressure weed control where chemical resistance and minimal drift are critical.

Applying Herbicides with Abrasive or Wettable Powders

Diaphragm pumps are engineered to handle abrasive formulas and wettable powders that quickly damage piston pump seals. The flexible diaphragm isolates these particles from the pump’s core mechanics, preventing premature wear and clogs. This design allows abrasive materials, such as kaolin clay carriers in powdered chemicals, to pass through without scoring internal components. The pump maintains consistent performance when spraying suspensions, ensuring an even and effective application of active ingredients across the target area.

Spraying Bleach Solutions or Mildly Corrosive Chemicals

The chemical-resistant materials used in diaphragm pumps make them the right choice for applying disinfectants, bleach solutions, and other mildly corrosive liquids. Internal components are protected from chemical degradation, which significantly extends the sprayer’s service life. This makes them suitable for sanitation tasks, mold remediation, or applying specific agricultural treatments that would corrode a standard piston pump. The sealed pump chamber also minimizes the risk of leaks when working with harsh chemicals, improving operator safety.

Low-Pressure, Targeted Weed Control on Sensitive Plots

Diaphragm pumps operate at a lower pressure range, which is an advantage for applications requiring minimal spray drift. This allows for precise, close-range treatment of weeds in gardens or near sensitive, non-target plants. The gentle application pressure produces larger droplets, reducing the risk of herbicides drifting onto desirable flowers, vegetables, or ornamental shrubs. This makes the pump highly effective for spot-treating weeds on lawns and along fence lines where accuracy is more important than high-pressure coverage.

Piston or Diaphragm Pump: Which Type Wins for Your Needs?

The choice depends entirely on the chemicals you spray; piston pumps excel with high-pressure, low-abrasion liquids, while diaphragm pumps provide superior durability for abrasive or corrosive formulas.

Choose a Piston Pump for High-Pressure, Fine-Mist Applications

A piston pump is the right choice when your work requires a fine, consistent mist delivered at higher pressures. It excels with low-abrasion liquid formulas like standard herbicides and insecticides, making it a go-to for uniform foliage coverage. This pump type delivers pressures up to 90 PSI, which is ideal for creating a fine spray that evenly coats plant surfaces. It is best suited for non-abrasive, water-soluble chemicals to avoid premature wear on the piston cylinder. Using wettable powders or aggressive chemicals can score the cylinder and degrade seals, leading to pressure loss and eventual failure.

Select a Diaphragm Pump for Chemical Versatility and Durability

A diaphragm pump offers superior durability and is compatible with a wider range of chemicals, including abrasive powders and corrosive solutions. Its enclosed design protects critical components from direct contact with the spray material, making it a reliable workhorse for multi-purpose use. This design allows it to handle abrasive materials like wettable powders and bleach-based solutions without significant wear. By sealing the pump mechanism from the chemicals, it reduces corrosion and extends the equipment’s service life. It operates at a lower pressure, typically up to 60 PSI, which is sufficient for most general-purpose spraying jobs.

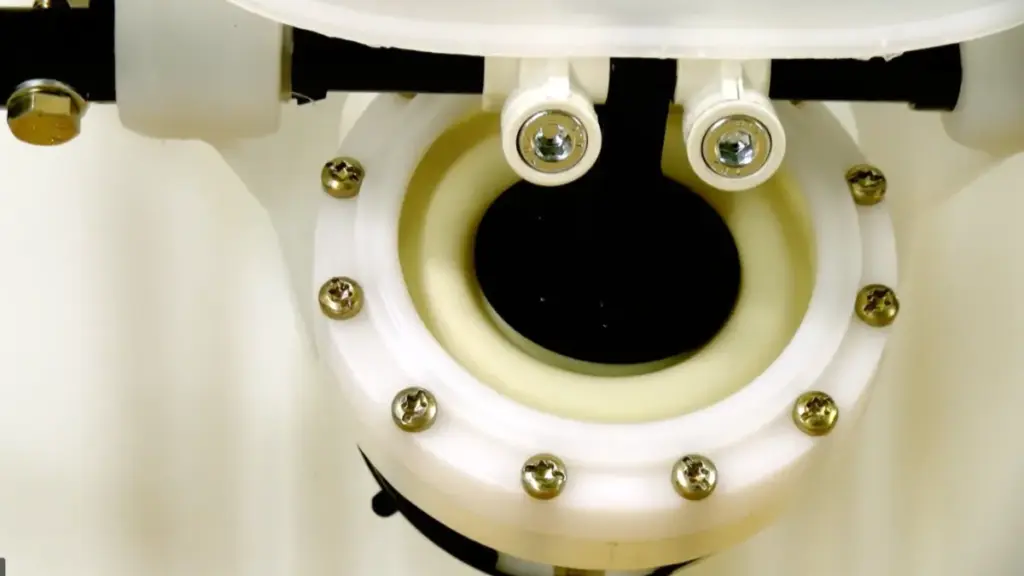

Why NEWTOP Precision CNC Machining Leads in Pump Durability

NEWTOP achieves superior pump durability by integrating in-house CNC machining for critical components with automated assembly, ensuring every unit meets precise engineering specifications for long-term reliability.

As a professional backpack sprayers and foggers manufacturer founded in 2003, NEWTOP combines long-term industry experience with advanced production technology. With over 20 years in agricultural and garden machinery manufacturing, the company focuses on building durable, field-ready spraying equipment for global markets.

NEWTOP uses upgraded PA66 reinforced with 30% glass fiber for key pump components, improving structural strength, chemical resistance, and dimensional stability. In addition, high-precision CNC machining ensures tight tolerances, smoother internal surfaces, and consistent sealing performance.

Conclusion

Choosing between a piston and a diaphragm pump is a critical decision for your backpack sprayer fleet. The right pump ensures compatibility with your chemicals, reduces costly downtime from component failure, and delivers consistent spray performance. This choice directly impacts both operator efficiency and the lifespan of your equipment.

If you are experiencing frequent pump failures or pressure loss, evaluate your current equipment against your application needs. For pump components engineered to withstand demanding chemicals and reduce maintenance cycles, see how our precision parts can improve your sprayer’s durability.

Frequently Asked Questions

Is a piston or diaphragm pump better for a backpack sprayer?

It depends on the application. Piston pumps deliver higher pressure for fine spraying, while diaphragm pumps offer better chemical resistance and durability when handling corrosive or abrasive solutions.

Can a piston pump handle bleach or powders?

It is not advisable. Bleach causes rapid degradation of standard rubber seals, and powders act as an abrasive that scores the cylinder walls. Diaphragm pumps are the engineered solution for these substances.

Why is my backpack sprayer pump losing pressure?

Common causes include worn seals, cracked diaphragms, clogged valves, air leaks in the hose, or debris blocking the nozzle. Regular maintenance and timely replacement of wear parts solve most pressure issues.

How often should I replace my sprayer pump seals?

Seal replacement frequency depends on usage intensity and chemical type. In heavy agricultural use, inspection every season is recommended. Replace seals when pressure drops or leakage occurs.

Which pump type is easier to prime?

Piston pumps are generally easier to prime because of their direct suction mechanism. However, properly designed diaphragm pumps with quality check valves also prime efficiently.

What is the maximum PSI for a diaphragm pump?

A standard diaphragm pump in a backpack sprayer typically reaches a maximum pressure of 60 PSI. This pressure is ideal for applications requiring larger droplets to reduce drift, such as applying wettable powders or herbicides.