Crush Inferior Products through Recognition and Accreditation

Reasons Why We Outperform Our Competitors

Our production scale, efficiency and discipline have always been at the forefront of the industry, whether it’s a peak purchasing season or a rush order, rest assured that you will receive your shipment on time as promised, without sacrificing the quality of the product.

More Than 500,000 Sets

70% Automation

6S Management System

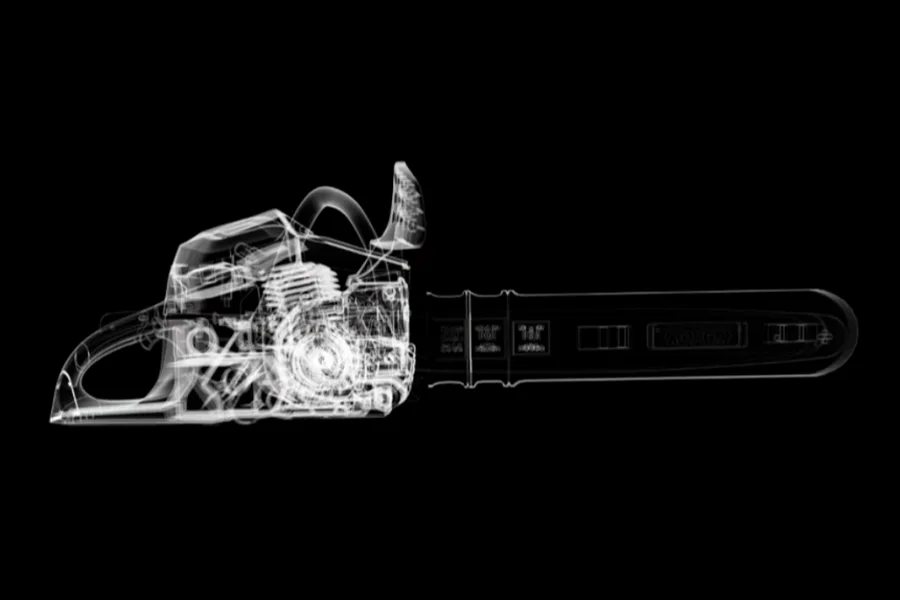

Top-tiered Outdoor Power Equipments in the Making

Equipment Feasibility Analysis

Our sales team listens to and gathers your product specifications and usage expectations, performs research on product parameters and market surveys, and completes feasibility and sample test reports, which are then turned over to R&D engineers for the next stage of development.

Product Design

When a product enters the design phase, engineers create a product development plan, specification sheet, and uniform spare part code while developing the three-dimensional structure. After the structural design has been reviewed, we move on to mold manufacturing.

Production Stage

When the product reaches the manufacturing stage, the technical department examines the mold production, parts proofing, and creates explosion illustrations, assembly drawings, and ROHS reports based on the drawings.

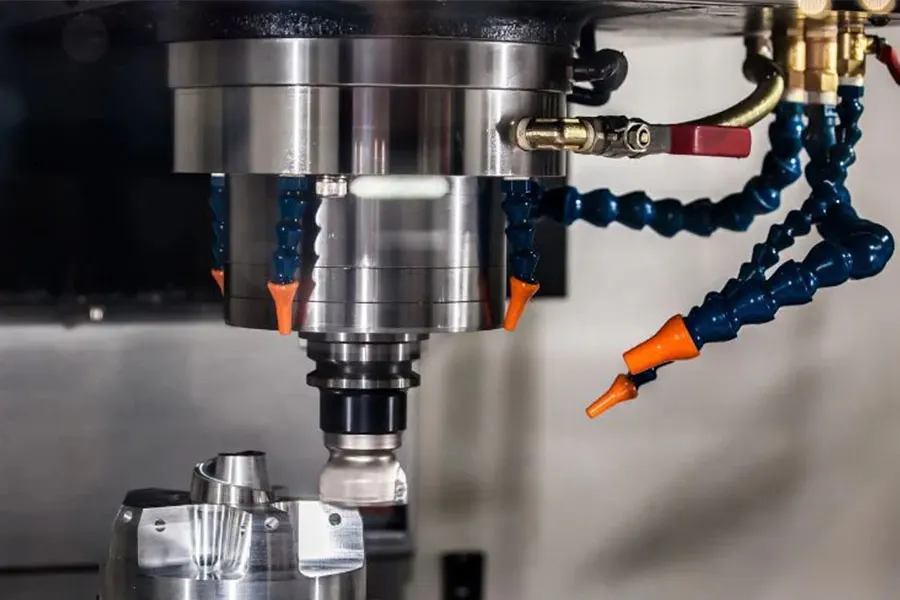

CNC Process

In our workshop, we employ state-of-the-art cnc machines for precision machining of core components, such as the crankcase for chainsaws. The automatic machining process leads to a uniform quality of the equipment.

Inspections & Testings

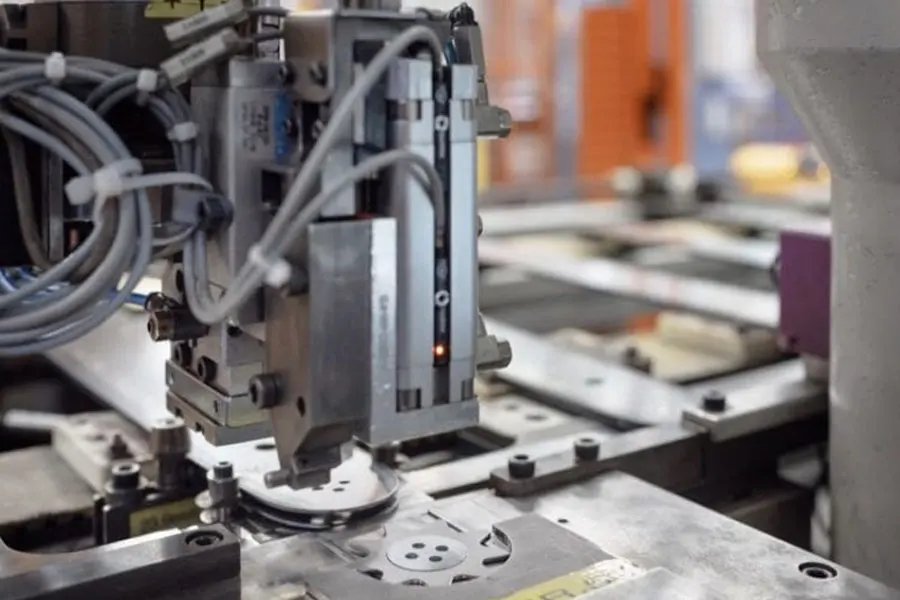

Custom Outdoor Power Equipment with Automation Enhancement

With the incorporation of automated production processes, we will increase the custom flexibility, decrease cost and waste, and satisfy your OEM demands while maintaining consistent quality.

Slash Hidden Costs & Defects

Outrun Demand Spikes

More Service Hours, Profit Longer

Learn More From 뉴탑